For instructions on how to turn off hardware acceleration see Additional Information. Users may wish to disable graphics hardware acceleration to determine if a particular issue is specific to their graphics adapter or graphics driver.

The use of graphics hardware acceleration on Windows platforms may cause display problems with some graphics adapters or drivers. Updated graphics tuning parameters are included in the graphicsConfig.env file, which can be downloaded and placed in your Abaqus installation. These changes are intended to configure Abaqus to best utilize individual graphics devices.

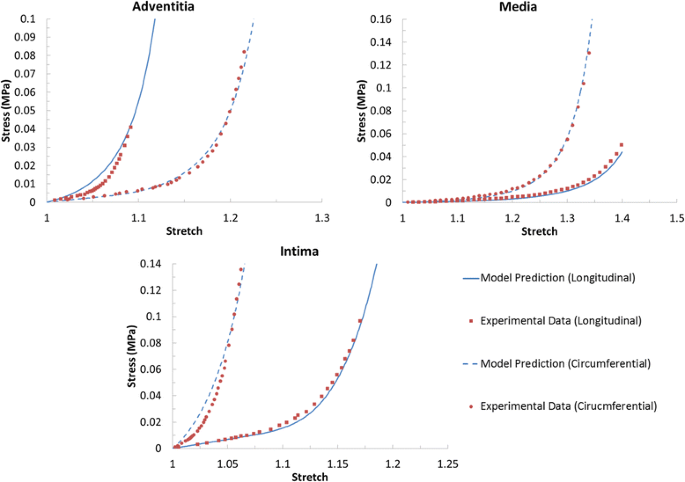

We may update graphics tuning parameters for graphics devices. We recommend that you use the tested driver version if you experience problems. NOTE: Newer driver versions for the graphics card listed on this page are expected to work, but may not be compatible. Other devices may be compatible but have not been tested. However, we cannot certify that these devices are completely compatible with all possible hardware and software configurations. Future work will focus on understanding the main biological determinants of regional and inter-individual variations of the material parameters used in the model.SIMULIA tests specific graphics devices to ensure adequate performance with Abaqus/CAE and Abaqus/Viewer the graphics devices that have been tested (or scheduled for testing) are listed in the tables below. Finally, this study demonstrated that a simple 2D finite element model with cohesive elements can reproduce fairly well the plaque peeling global response. The results revealed that only the elastic parameter was significantly different between the two groups, ApoE -/- Col8 -/- plaques being less stiff than ApoE -/- plaques. The elastic parameter of the plaque and the CZM interfacial parameter were successfully identified for a cohort of 11 mice. The model parameters were calibrated by minimizing the quadratic deviation between the experimental force displacement curves and the model predictions. Each constituent of the plaque was modeled with a neo-Hookean strain energy density function and a CZM was used for the interface. To this end, a 2D finite-element model of each plaque was solved using an explicit integration scheme. In this study, material parameters of a CZM were identified for the first time on two groups of mice (ApoE -/- and ApoE -/- Col8 -/-) using the measured force-displacement curves acquired during delamination tests. Finite element analyses using cohesive zone models (CZM) can be used to predict the fracture of atherosclerotic plaques but this requires setting appropriate values of the model parameters.

0 kommentar(er)

0 kommentar(er)